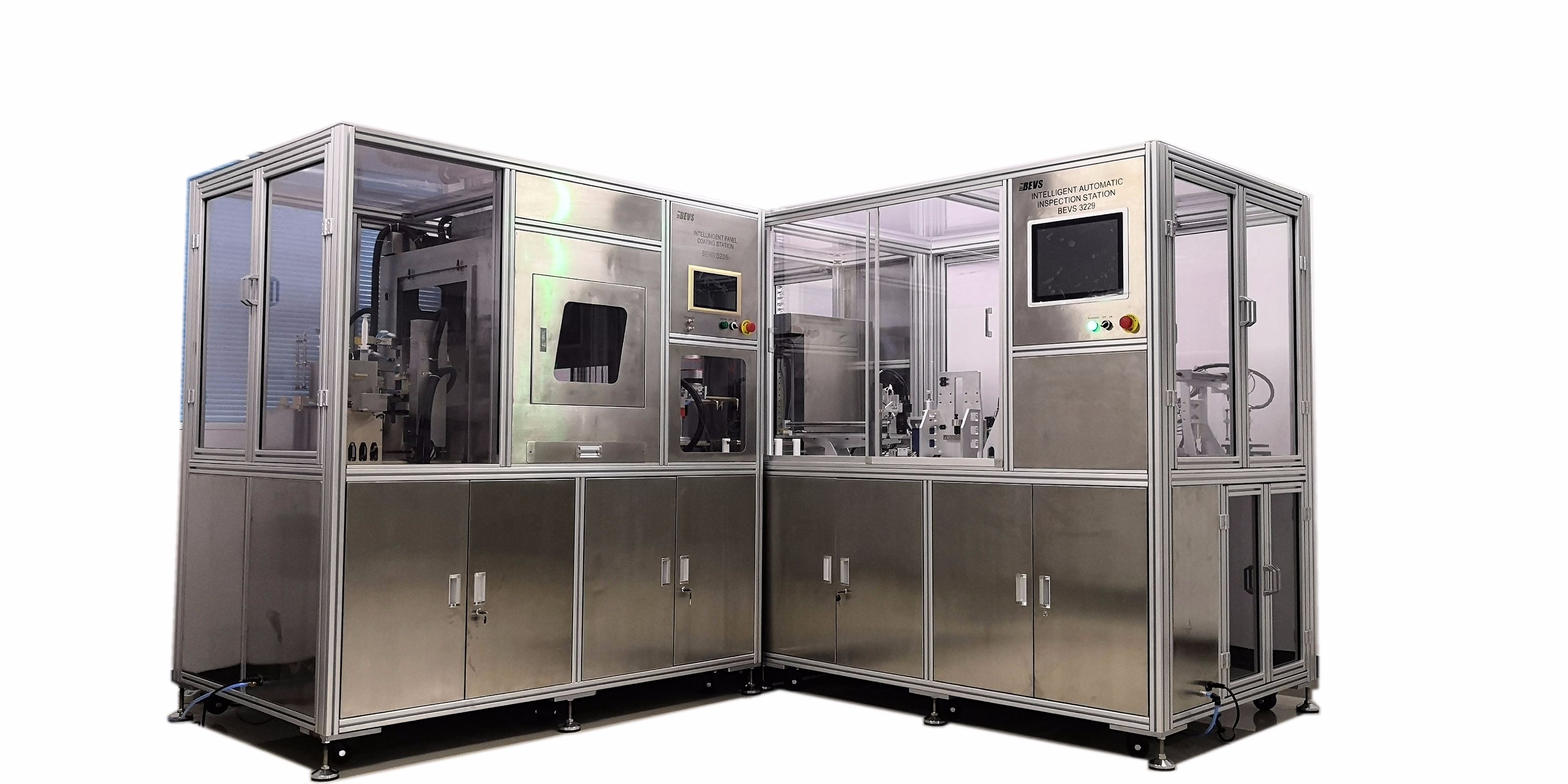

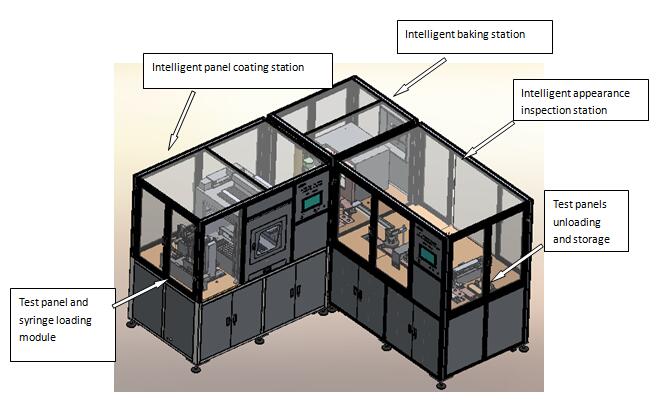

The BEVS Intelligent Multi-Combined Station is based on BEVS intelligent workstations with high level of integration and scalability. The system realizes intelligent automatic test and inspect of various properties of related products such as paint, ink, resin etc. fully automated from sample loading to unloading. The efficiency is increased excess 50% than traditional.

This system can be reduced human errors and increase repeatability and reliability. It is easy to transport, easy to disassemble, and with a variety of testing and inspections can be freely combined.

The workstations are connected by a quick interface: the machine uses a connecting rail or a mechanical arm, the appliances are connected by a universal cable.

A single workstation can be worked independently and can complete one or more testing or inspection projects.

Multiple workstations can be stitched together quickly to realize multi-inspections and testing.

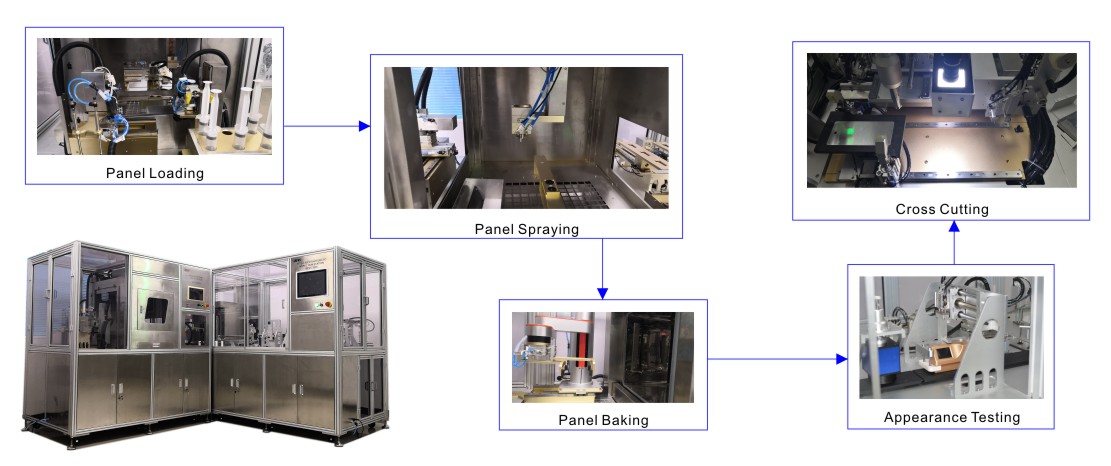

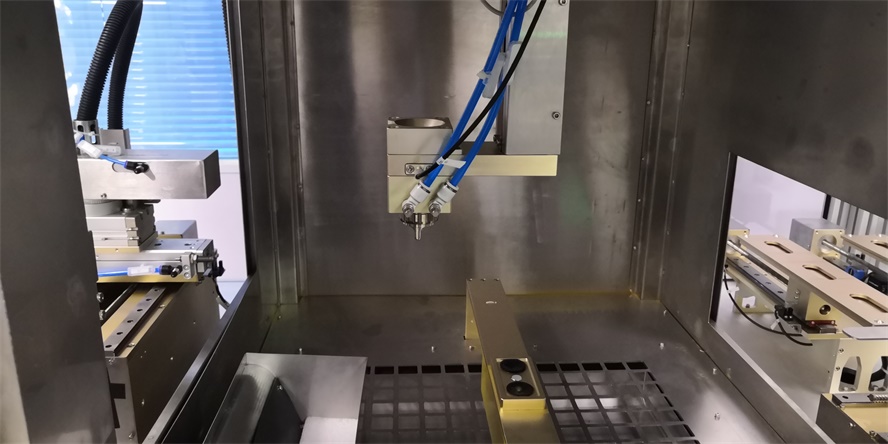

Intelligent panel coating station

Click here for details.

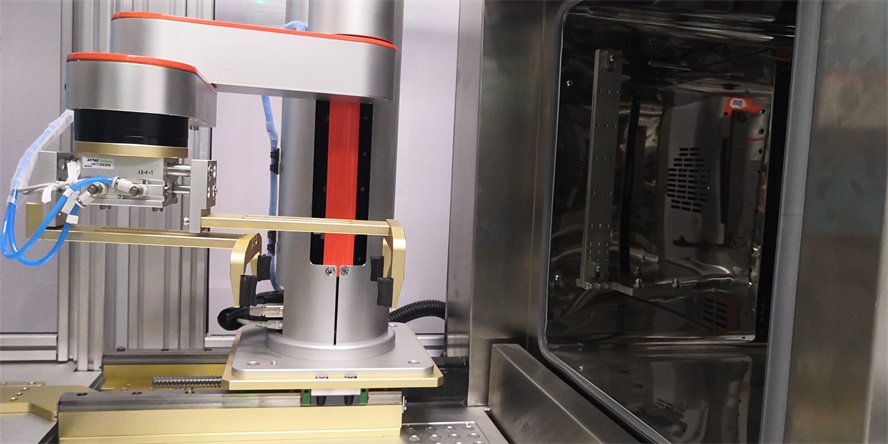

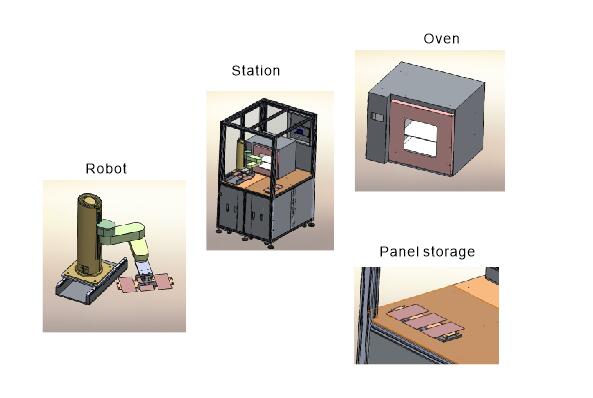

Intelligent baking station

It is the key station to connect intelligent panel coating station and intelligent appearance inspection station. The coating panels will be curved in this station, it mainly composed of an oven, four-axis robot and test panel sorting unit.

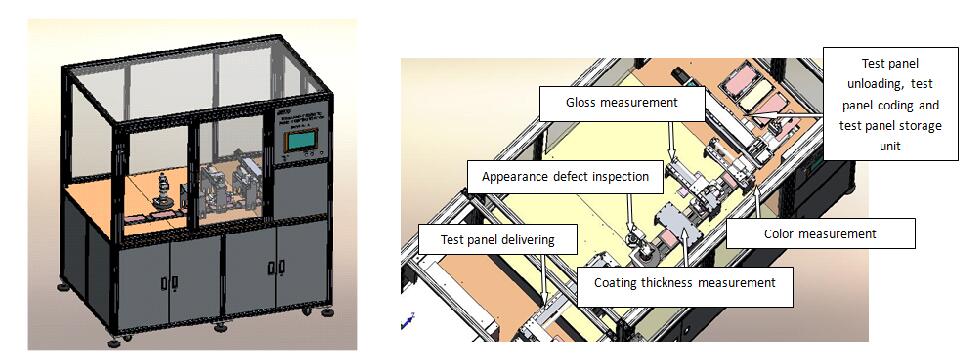

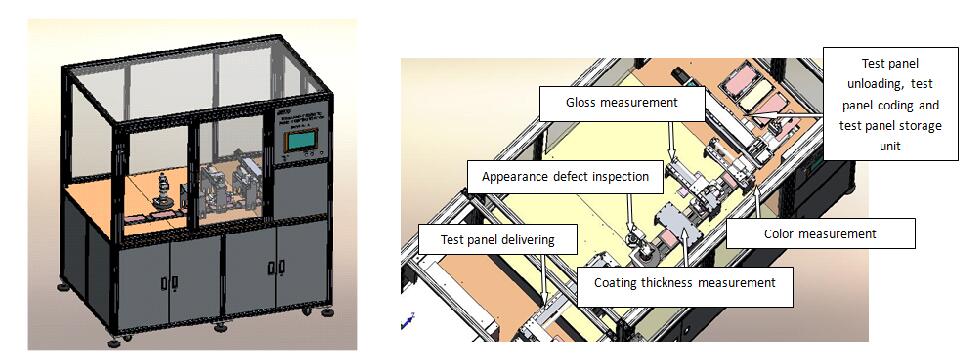

Intelligent appearance inspection station

The intelligent appearance inspection station is for inspecting the coating performance. It can realize the on-line inspection of the coating thickness, gloss and color etc. The panel through front two stations will be coded, a label with barcode will stick on the panel uncoated side. Through the barcode, all info including the paint, spray setting, drying time is traceable. The station is mainly composed of test panel delivering, appearance defect inspection, coating thickness measurement, gloss measurement, color inspection, test panel unloading, test panel coding and test panel storage unit.

Software system

The software architecture of the BEVS intelligent testing and inspection system consists of: physical execution, network link, central control, software system, and application management. It is real-time communication of data each other.

Physical execution: consists of motion mechanism and smart instrument, connected to the central control through network unit.

Network link: responsible for the conversion of data communication. It converts different communication modes of instruments on the physical execution into a set of standard communication control protocols to suit the system.

Central control: the stand-alone control software of each station. For a single station working, central control, network link, and physical execution will combine into a control model to control all the motions of station. When multi stations are combined into a laboratory system, the software of each station works separately and communicate with the other stations. When the system software is missing, it is also possible to communicate and coordinate the entire laboratory system to complete the task normally.

Software system: mainly the central control software, which is responsible for coordinating the station software in the system by a PC. The status of all devices can be displayed and also the operation status. A report is automatically generated after each test is completed and stored on the server.

Application management: including data management, data server, other platform like APP communication and other interfaces.

Multi-station parameters

No. |

Description |

Specification |

1 |

Paints |

Water or solvent base |

2 |

Paint types and capacity |

6 x 30ml |

3 |

Test panel (substrate) |

L(120-180) x W(50-90) mm, Thickness(1-10) mm |

4 |

Paint viscosity |

1-20000mps |

5 |

Spray speed |

X-axis: 10-100mm/s, Y-axis: 10-100mm/s |

6 |

Stroke length |

X-axis: 210mm, Y-axis: 210mm |

7 |

Test panel storage |

Max. 50pcs |

8 |

Four-axis robot speed |

10-500mm/s |

9 |

Oven drying time |

0-60min |

10 |

Oven drying temp. |

Ambient ~ +300℃ |

11 |

Oven capacity |

6 pcs test panels |

12 |

CCD vision camera speed |

0-50mm/s |

13 |

Thickness gauge |

Range: 0-500µm, accuracy: 0.5µm |

14 |

Gloss meter |

Range: 0-2000GU, accuracy: 0.3GU |

15 |

Orifice of colorimeter |

Ø8mm |

16 |

Light source of colorimeter |

D65 |

17 |

Repeatability of colorimeter |

△E*ab<0.1 |

18 |

Unloading panel storage |

Max. 20 pcs |

19 |

Electricity supply and compressed air |

Voltage: 220V/50Hz Power: 2.5 KW Air pressure: 0.7 Mpa (7 bar, no oil and water) |

20 |

Working temp. |

+15-35℃ |

21 |

Humidity |

20-80% RH (no condensation) |

22 |

Dimension |

L 2200 x W 2150 x H 1800mm |

23 |

Weight |

Net. 680kg |

Other stations to be linked

Cross cut etc.