BEVS AI Viscometer Leads Intelligent Coatings Testing in Bangkok & Shanghai

Category: Exhibition

Date: 2025-09-14

Click: 5562

Author: Ivy

Collection:

As Bangkok’s tropical heat meets Shanghai’s morning light this September, BEVS’s booth has emerged as a hub of global innovation. Showcasing at both the China Coatings Show in Shanghai and the Asia Pacific Coatings Show in Bangkok, BEVS unveiled breakthrough solutions: AI viscometers with voice control, wet abrasion scrub testers with intelligent recognition, and adjustable film applicators with micron-level precision. Together, these advances mark a new chapter for Made in China in coatings testing.

This is more than a product display — it is a global dialogue on how intelligent technology is reshaping the logic of testing.

Dual-Exhibition Resonance:

A Global Showcase of AI Technology

At Hall N3 of the China Coatings Show in Shanghai, BEVS’s AI Wet Abrasion Scrub Tester is staging a precision revolution at the millimeter level.

Like the sharp eyes of a hawk, its high-definition camera captures the critical moment of a coating’s 12,168th scrub, reducing the traditional 40% margin of human error to nearly zero.

As one director from a building materials testing institute exclaimed, “In the past, we had to stare at samples until our eyes blurred. Now, the machine understands the coating’s fatigue threshold better than we do.”

At the Bangkok booth, BEVS’s AI Viscometer captivated international visitors with its voice-interaction feature. The simple commands “Start testing” and “Switch display” were instantly executed, with the instrument automatically adjusting speed and collecting data. This voice-driven testing model not only reduces manual operating costs by 60%, but also provides early warnings of potential production risks.

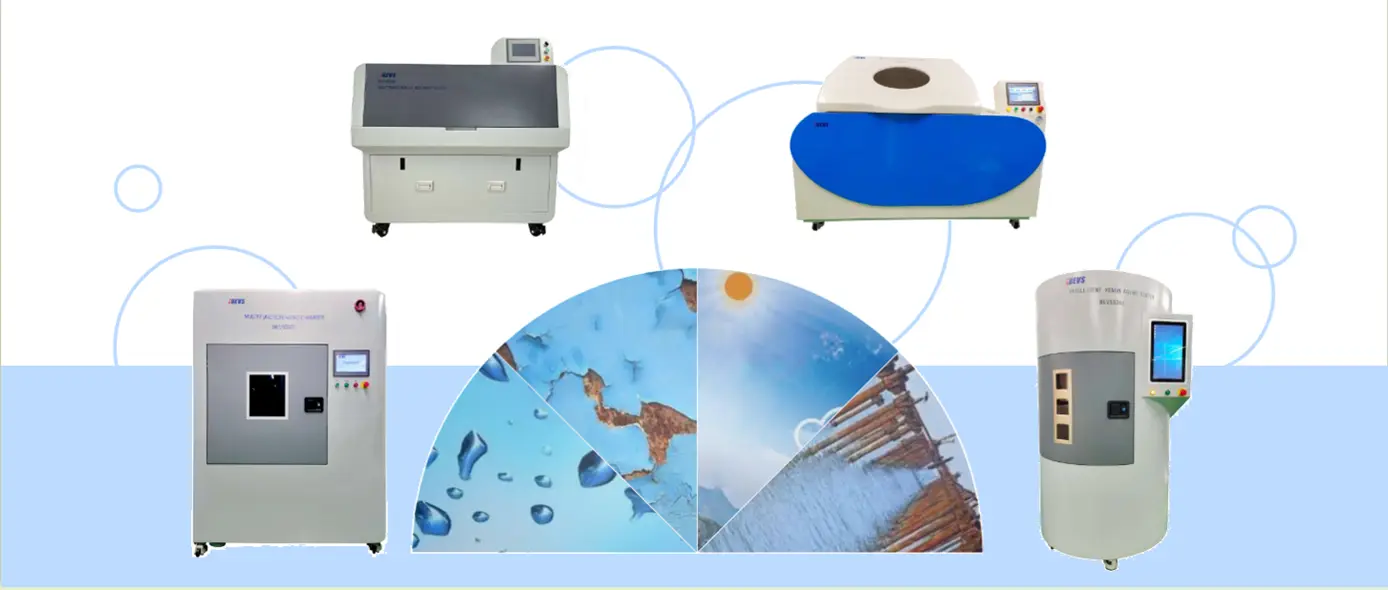

These two technology showcases, staged 4,000 kilometers apart, highlight BEVS’ intelligent integration across the full spectrum of coatings testing. From the AI Wet Abrasion Scrub Tester and Tabletop Xenon Aging Tester unveiled in Shanghai, to the AI Viscometer showcased in Bangkok, BEVS’s product portfolio forms a smart arsenal for the testing industry: some excel at accelerated simulations of years of natural aging, while others specialize in micro-level analysis of coating mechanics—together building a full-chain intelligent defense from R&D to production.

Breaking Barriers:

From ‘Tool’ to ‘Intelligent Partner’

BEVS’s product innovation has always targeted the industry’s most persistent pain points.

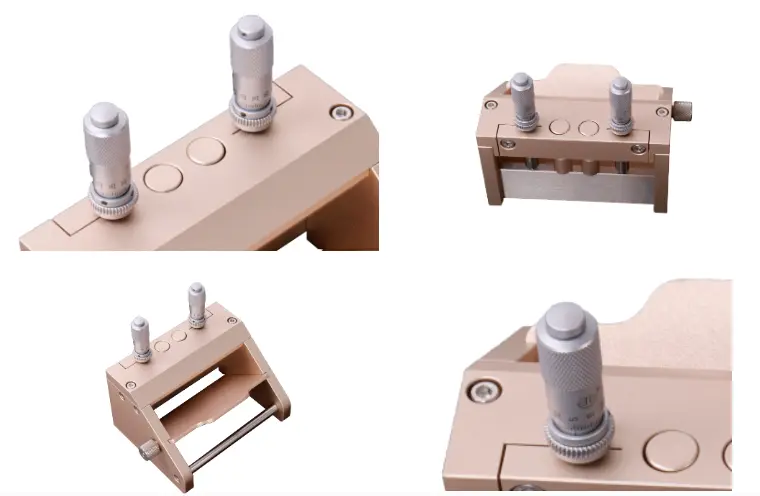

The Adjustable Film Applicator was born out of researchers’ long-standing frustration with uneven film application. Its micrometer adjustment system controls thickness in precise 10 μm increments, while the spring-suspension design locks error within ±2 μm. This level of accuracy means that whether for nano-scale conductive coatings or 3,500 μm encapsulation layers, a simple twist of the knob ensures instant adaptation.

Even more ingenious is the magnetic quick-release design: the blade can be detached in just three seconds, cutting cleaning time from 15 minutes to only one. As one battery lab reported, “Now we can run three more comparative tests per day, and the R&D cycle has been shortened by one-third.”

The Automatic Panel Sprayer has redefined the efficiency limits of coatings quality inspection. Its dual-spray gun system delivers uniform atomization, improving coating thickness consistency by 60%. Combined with automatic anti-settling stirring, color deviation is reduced to an industry-leading 0.5 ΔE.

A leading coatings company calculated that with this equipment, paint waste is cut by 50% and spraying efficiency triples. “Tasks that used to take three people a whole day can now be completed by a single machine in four hours, with digital records automatically generated,” the company reported.

Behind these innovations lies BEVS’s deep understanding of human–machine collaboration—not replacing people with machines, but letting machines handle repetitive tasks, freeing human creativity.

Standard Redefined:

A Full-Chain Solution for Anti-Corrosion Coatings Testing

In the multi-billion-dollar global market for anti-corrosion coatings, BEVS’s intelligent testing solutions are emerging as the guardians of quality.

To meet the performance verification needs of eco-friendly products such as water-based coatings, BEVS has built a “physical performance + weathering” testing matrix that sets the industry benchmark:

The Intelligent Krebs Viscometer strictly follows GB/T 9269 standards, ensuring comparable data on application flow properties.

The Automatic Pull Off Adhesion Tester operates according to ASTM D4541, precisely quantifying the coating’s bonding intimacy with the substrate.

The Intelligent Xenon Aging Tester simulates full-spectrum sunlight, exposing coatings to the equivalent of several years of outdoor aging in just a few thousand hours.

This full-chain capability is particularly critical in high-end sectors such as marine engineering and rail transit.

When a ship coatings manufacturer needs to evaluate corrosion resistance under alternating spray and damp-heat conditions, BEVS’s Intelligent Multifunctional Salt Spray Tester automatically switches test environments in compliance with ISO 12944-9.

When photovoltaic coatings require UV aging resistance, the UV Weather Tester precisely replicates the intense radiation of desert environments.

True to the philosophy of “Excellence through Quality, Innovation through Precision,” BEVS’ solutions go beyond meeting today’s standards—they are shaping the testing standards of the future. By leveraging AI algorithms to forecast performance decay curves and big data to optimize formulation ratios, BEVS is transforming testing from post-event verification to pre-emptive enablement.

From customers marveling at the AI Wet Abrasion Scrub Tester in Shanghai, to clients in Bangkok giving a thumbs-up to the voice-controlled viscometer; from the uniform coatings drawn by the Adjustable Film Applicator in the lab, to every drop of paint saved by the Automatic Panel Sprayer on the production line — BEVS’s dual-exhibition journey is, at its core, a gentle disruption of traditional testing through intelligent innovation.

When more than 130 patents are transformed into practical solutions for industry pain points, and when flexible “non-standard customization” services adapt to diverse sectors, BEVS proves that true innovation is never a mere showcase of technology. It is about turning every instrument into a precise partner for its users—leaving a solid mark of Made in China in the coatings industry’s transformation toward high-quality development.