PRODUCT

- Dispersion

- Density / Grinding

- Viscosity

- Application of Film

- Automatic Panel Sprayer

- Mini Automatic Film Applicator

- Automatic Film Applicator

- Film Application Kit

- Single Sided Applicator

- Two Sided Applicator

- Four Sided Applicator

- Four Sided Applicator With Reservoir

- Eight Sided Applicator

- Cube Applicator

- Digital Adjustable Applicator

- Adjustable Applicator

- Sagging Applicator

- Levelling Applicator

- Bar Coater

- Bar Coater Handle

- Hiding Power Chart

- Automatic Panel Spray Station

- Payne Permeability Cup

- Auto Spray Device

- Drying Time

- Thickness

- Temperature

- Color / Gloss

- Adhesion

- Hardness

- Deformation

- Abrasion, Scrub / Washability

- Degradation

- Weathering Testing

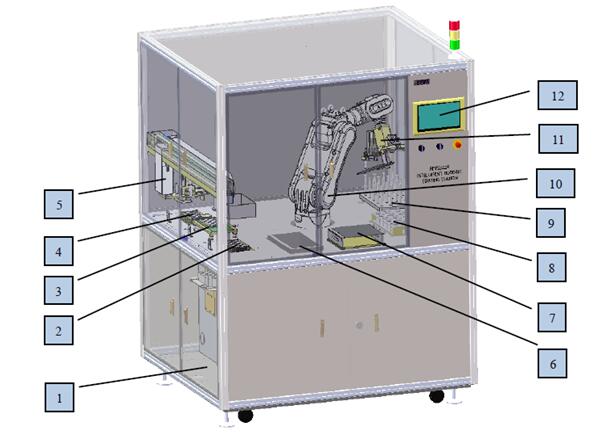

- Intelligent station