|

مركز التصميم |

مراقبة الجودة والتفتيش

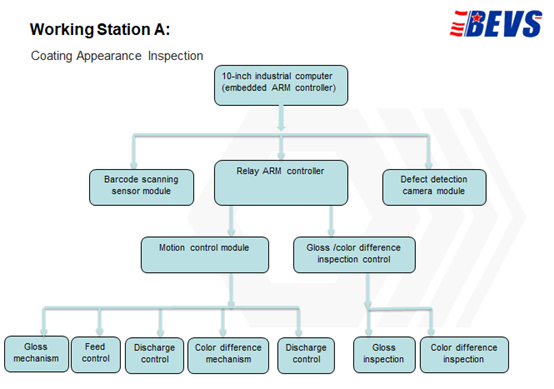

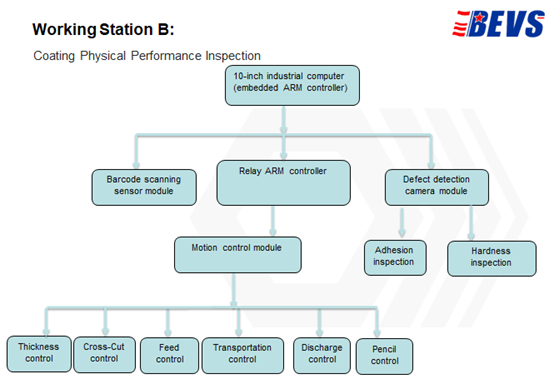

BEVS can customize the professional intelligent QC and Inspection program according to the different testing requirements of customer, and realize the intelligent automatic inspection of the performance of raw materials, coatings, inks and etc. Advantages: *Real-time data encrypted transmission *Automatically complete testing *Remote command system *Get data, analysis, and results reports anytime, anywhere *Shared with intelligent, automated workshop production *High efficiency and greatly reduce inspection costs *Compatible with many different testing projects *Fast automatic loading and unloading 1) Intelligent Inspection Working Station

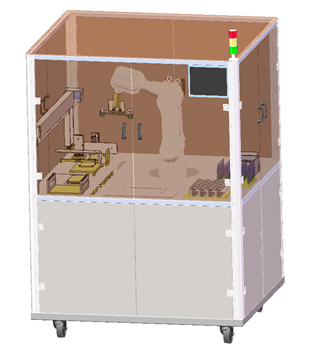

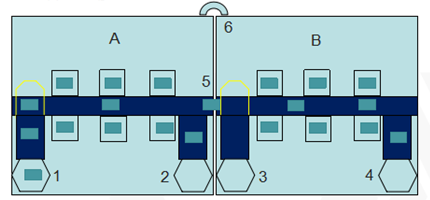

Example: Introduction: BEVS3228 Intelligent Robotic Coating Station is integrated by intelligent instrument, robot, automatic control system and testing material. The robot automatically completes the loading and unloading to achieve rapidly automatic drawdown, greatly improves the reproducibility and efficiency of the drawdown coating, and obtains the coating film which has the uniform physical, appearance and chemical properties. All kinds of instability caused by the factors such as velocity, pressure and direction in the application process are eliminated.

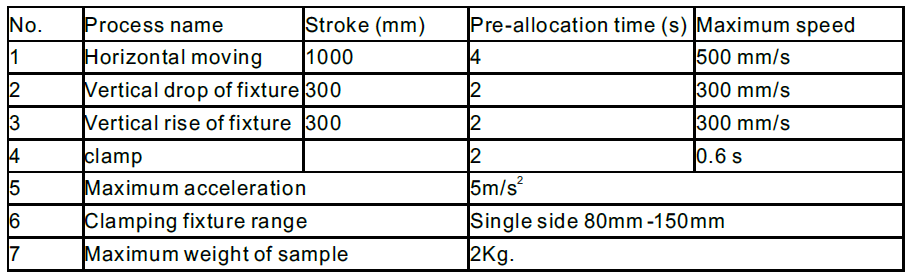

Features: -With AI sensor -Real time Data encrypted transmission -Testing automatically -Free combination of instruments and equipment -System work by remote command -Data, analysis, and result report can be obtained at anytime and anywhere -Sharing with intelligent and automated production workshop -Shorten the R & D and testing cycle -High efficiency and greatly reduced R & D cost -Data saving and output -Fast automatic drawdown with different coatings -Fast automatic loading and unloading material -Quick replacement of paints Robot Parameters:

Drawdown Parameters: -Moving speed: 10-100mm/S -Length of stroke: 20-180mm -Substrate size (maximum): 150x70mm -Test platform: fine grinding aluminum alloy plate -Coating device: Bar Coater System parameters: -Continuous coating drawdown speed: 40 s/pcs -Duration of working: 7x 24h -Compatible coatings: 10 kinds of paints -Maximum storage standard samples: 200 pcs -Maximum storage panel bracket: 20 pcs -Maximum storage coated panel: 20 pcs -Voltage: 220V/50Hz -Power: 2.5 KW -Air pressure: 0.5 Mpa (no oil and no water) -Temperature: 0-45 ℃ -Humidity: 20-80% RH (non - condensation) -Vibration: <4.9 m/s -Workstation size: 1400X1200X1900 mm (L X W X H)

For Coating Equipment: Automatic pick-up and discharge, automatic unloading of paint sample and pipette recovery Functions: -Store many panels at a time and collect it automatically and quickly -Store several Bar Coaters at a time and get the Bar Coaters and operate automatically and quickly -Paints storing device, load and upload the paint by robot -Drawdown by robot -Ultrasound cleaning for bar coaters, save time and water, more environmentally friendly -Fully automatic operations in the testing process, automatically collect panel into shelves -Modular designs, convenient maintenance and enable rapidly upgrade -A variety of drawdown modes can be selected. Drawdown for many times in one kind of coating and drawdown in turn in different coatings Application: Coatings, inks, packaging, printing, chemicals, universities, research institutes, testing institutions etc. Order Information: BEVS3228 Intelligent Robotic Coating Station. Other Intelligent Robotic Coating Station can be customized upon request |